- GST No. 24AAKFP0506C1ZU

- Send SMS

- Send Email

Electroplating Rectifier

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Wholesaler |

| Material | COPPER |

| Application | Industrial Use |

| Condition | New |

| Click to view more | |

Preferred Buyer From

| Location | India ( Gujarat only) & All other countries |

Product Details

The Electroplating Rectifiers are widely used in Electroplating, Anodizing, Hydrogenation, and all other electrochemical processes. These are tailor-made, covering a wide range from 500 TO 25000 AMPS at different output DC voltage as per requirement.

Salient Features :

- Designed for 100% Continuous Duty Cycle

- Compact Design for Space Saving

- Lesser Power Consumption

- Negligible Maintenance

- Tested at Each & Every Stage of Manufacturing

- Liberal Design & Rigorous Testing of the Equipment Enables Trouble Free Service for Long Life.

Components :

- OTI

- Oil Pocket

- Oil Level

- Radiators

- Oil Circulation Pump

- Bus Bars

- Siica Gel Breather

- Butterfly Valves

- Earthing Terminals

- Oil Drain Valve

- UNI Directional Wheels

- Window for Diodes

- Oil Tank Indicator

- Lifting Lugs

Brief Specifications :

- Input Voltage : 380 - 440 Volts, 3- Phase 50 Hz. AC supply or any other voltage

- Output Voltage : Fixed Rated maximum DC voltage or variable from zero to maximum rated voltage

- Output Current : Rated maximum DC current

- Temperature Rise : Less than 45° C above ambient at the top of the oil

- Efficiency : Depends on voltage current rating of rectifier

- Ripple Content : Less than 5%

- Insulation : 'A' class for oil cooled

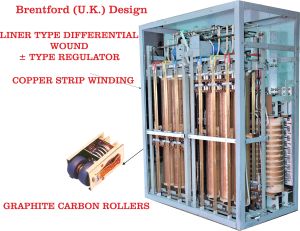

Why the regulator control is superior to thyristorised control in rectifier? Inner View

- In plating application the regulator is better & technology is adopted in Germany and Europe because of as explained in advantage.

- Other manufacturers of rectifiers have shifted to thyristors because they do not have the technology of rolling carbon roller regulators.

- Manufacturers of rectifiers claim that thyristor-controlled rectifier has less losses than regulator. They compare thyristor with sliding carbon type regulator. In our case their claim is not true. We use vertical coil type rolling carbon regulator. The copper section is three times so the losses are almost 1/6 or 20%.

- In our regulator the roller moves on both sides of the coil to give ± 440 V or ± 254 V output. We design the rectifier in 'Q' connection in which the regulator current is half the line current so losses are less and life is much more.

Starting Circuitry: Power Rectifiers are designed for 3 phase 50 Hz. AC input supply & are available for operations at any voltage between 380 and 440 volts, in India but can be designed for 60 Hz AC and any other voltage available. It is recommended that the input to the rectifier should be connected through a proper protective device, to provide positive protection to personal and the system, in the event of maintenance or in case a fault occurs. DC Output Control : The function of the variable output controls is to control the voltage or current or its operating range by varying input voltage to the main transformer primary. The DC output voltage variation is achieved steplessly 0-100% by means of an On Load roller type power make voltage regulator. Advantages of Roller Type Regulator :

- No. waveform distortion at any load, Electrical wave from is like a moving wheel. Fo 50% Rated Voltage the Dia of wheel is reduced accordingly i.e magnitude for a wave is decreased

- Higher power factor of more than 98 is achieved

- The system is simple and can be repaired and maintenance even by simple mechanic

- The cost of spares is very negligible

- Copper section for particular current is 3 times than conventional make

- Carbon roller rolls on coil and has trouble free life of more than 20 years

- Over all losses are less

Advantages of Conventional Make :

- Wave form distortion in thyrsorised type, It is like cutting the wheel by 50% and then moving the wheel. i.e wave from is cut as shown at full magnitude

- The power factor is lower between 0.5 to 0.75

- The system is specialized and need specially trained Electronic Engineer to repair and maintain

- The cost of replacement is very high

- Copper section for particular current in conventional make is 1/3

- Carbon brushes slide on coil, have less life due to sliding on coil & breaks regularly

- Over all losses are less

POWER ENGINEERS COMPANY offers a complete range of rectifier equipment ranging up to 0 - 1100 volts / 25,000 AMPS for all following applications and provides engineering, design and technical support in choosing the right solution/equipment.

DC Rectifiers used in Electrochemical Plants like Potassium & Sodium Chlorate, Soda-ash, Caustic chlorine Production, Copper, Aluminium, Zinc refining all require modest voltage and high DC current. DC Rectifier is also required in other industrial process like Electroplating, Hydrogenation, Electrolysis, chlorination. Such continuous process industries look for a reliable, economical and trouble free form of DC power supply system.

Applications

- Electroplating, Anodizing, Galvanising, Electro-coloring

- Hydrogenation, Chlorination, Electrolysis

- Electrochemical - Sodium, potassium salts

- Electro-smelting, Aluminum, Copper, Zinc.

- Industrial Power Supplies, Cathodic Protection

- Heating, Magnetisation, Ionisation