- GST No. 24AAKFP0506C1ZU

- Send SMS

- Send Email

1 Lac - 5 Lac / Piece

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Distributor |

| Brand Name | PEC |

| Material | Copper |

| Cooling Type | Oil Cooled |

| Click to view more | |

Product Details

Operating Type

Semi Automatic

Usage

Industrial

Certification

ISO 9001:2008

Packaging Type

Wooden Box

Input Voltage

440V

Output Voltage

0-1100 V

Phase

Three Phase

Total Carbohydrate

3 Year

Country of Origin

India

Corrosion Resistance

Yes

Product Code

2000 KVA

Port

JNPT MUMBAI

Payment Terms

L/C, D/P, T/T

Delivery Time

45 DAYS

Packaging Details

WOODEN PACKING

range 0- 33,000 volts 3 - phase, up to 5000 kva

PRINCIPLE OF OPERATION: The Variable Voltage Supply/ Regulator consist of following basic components depending on the rating of the equipment.

1) Step up Transformer

2) Buck boost transformer

3) Rolling contact type voltage regulator

4) Automatic control gear

Variable Voltage Supply/ Regulator with constant Input and variable output. It consists of a Step up Transformer, 6 nos. Regulators and Buck Boost transformer. This circuit is normally used to Vary on load voltage when the regulator used in conjunction with buck/boost transformer and step up transformer.

The equipment are available with following control devices:

a) Manual version

b) Motorised version

c) Remote control

In manual version a Hand wheel T Handle is provided and desired output voltage can be obtained by rotating the Wheel Handle manually.

In case of motorized version and servo motor will be provided which can be operated by two sets of push buttons or toggle switch for raising and lowering the output voltage.

In case of remote control arrangement one extra set of push buttons will be provided in your main panel from where the operator would be able to maintain the desired voltage with the help of those push buttons.

DESCRIPTION

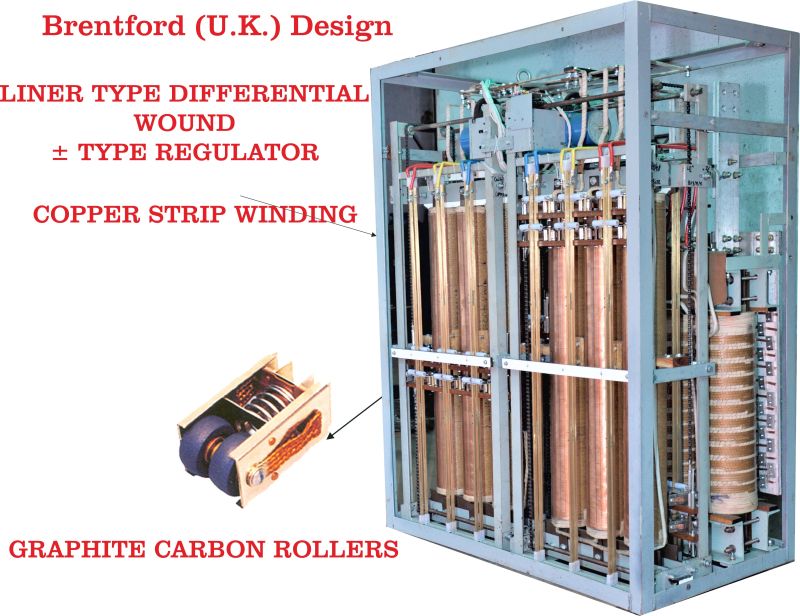

ROLLING CONTACT REGULATOR

This is essential a Continuously tapped auto wound transformer having helical coils mounted on a conventional laminated transformer core. However, the regulating winding is designed as a single layer type giving longer and slimmer version of the transformer coil but in principal it is the same.

The regulating winding is varnished and baked to improve rigidity and ensure that the construction is non hydroscopic. After proper treatment longitudinal/track is ground on the coil to form a bared copper surface with the winding wire covering providing inter turn insulation. Graphite rollers , assembled on carrier boards, traverse throughout the length of the coil track. These rollers are connected electrically with the output terminals and as they are driven over the track a variable voltage is obtained. The Regulator may be of one sided or can be made double sided. In case of double sided Regulator both side of regulating winding is bared and allows rollers to be driven in opposite direction on either side of the coil. In such cases carrier boards are provided on both sided of the coils and the output terminals will be taken out though balancing transformer.

The contact carrier is driven by a hand wheel / T–Handle or motor which is coupled to the chain drive. Limit switches operated by the carrier board are fitted to prevent over run. In case of your specific requirement additional limit switches will be fitted for minimum position inter-locking along with the auxiliary circuit. The power supply of the motor is derived from the Regulator unless otherwise specified. The entire regulator assembly is housed inside a rigid M.S.Tank filled with oil. The Hand wheel / T – Handle, Motor push buttons etc. is fixed up inside a separate sheet steel box which is attached to the main tank. Wherever automatic control is required the solid stat voltage sensing relay is also provided inside a sheet steel box fitted along with the regulator tank.

Looking for "Variable Voltage Transformer" ?

Piece(s)